Main menu

Aluminium composite. (ACM)

Use this list to explore more.

Aluminium composite cut with waterjet

An in-house option.

Cutting aluminium composites with high pressure water is not something most sites can offer. That's a shame because waterjets are very useful for projects where very fine profile shapes need to be cut from acm material.

Normally aluminium composite material (ACM) is cut in straight sided panels with a saw blade or cut into complex shapes using a carbide router bit. Whilst there is nothing wrong with either technique water cutting can offer something extra.

Smaller.

The attraction of water cutting is the size of the cutting "tool". When routing aluminium composite it's normal to use a 4mm wide cutting tool, a 3mm wide tool for "finer" cutting. Cutting aluminium composite with a water jet allows you to use a much smaller "tool", around three times smaller in fact.

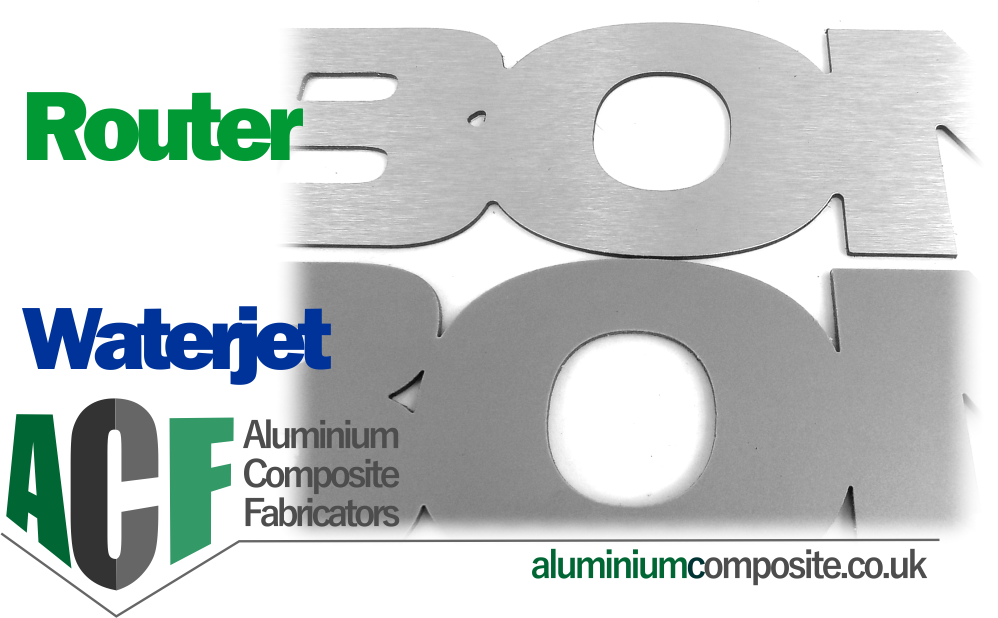

If we look at this image we can see a standard router cut piece of composite. In sharp corners definition is starting to be lost; the router bit is just too big to accurately recreate the shape we programmed.

The bottom image is the same CAD file processed through a CNC water jet cutter. We can see that the part detail is crisper with sharply angled corners and more definition; especially where the letters B and O intersect.

For the majority of aluminium composite projects using standard CNC routing techniques delivers all we need. There are some projects where the extra precision and shape detailing offered by water jet cutting can make all the difference. Other advantages of this kid of water cutting include;

Stacking.

Water jetting technology lets you employ a stack cutting strategy; several sheets of aluminum composite can be stacked on top of each other and cut in a single pass; a very efficient technique.

Shared line.

If you've used aluminium composites before you may have encountered shared line cutting before; a technique which uses one programmed cut to make the left hand of one part, right hand of another. Because the cutting jet of water is so small it means shared cutting can be taken to the highest level, the absolute minimum of waste can be ensured

Profiles

Aluminium composite cut with water jet is limited to flat 2d parts only. It's not possible to partially score or rebate the material using this type of CNC technology.