Main menu

Aluminium composite. (ACM)

Use this list to explore more.

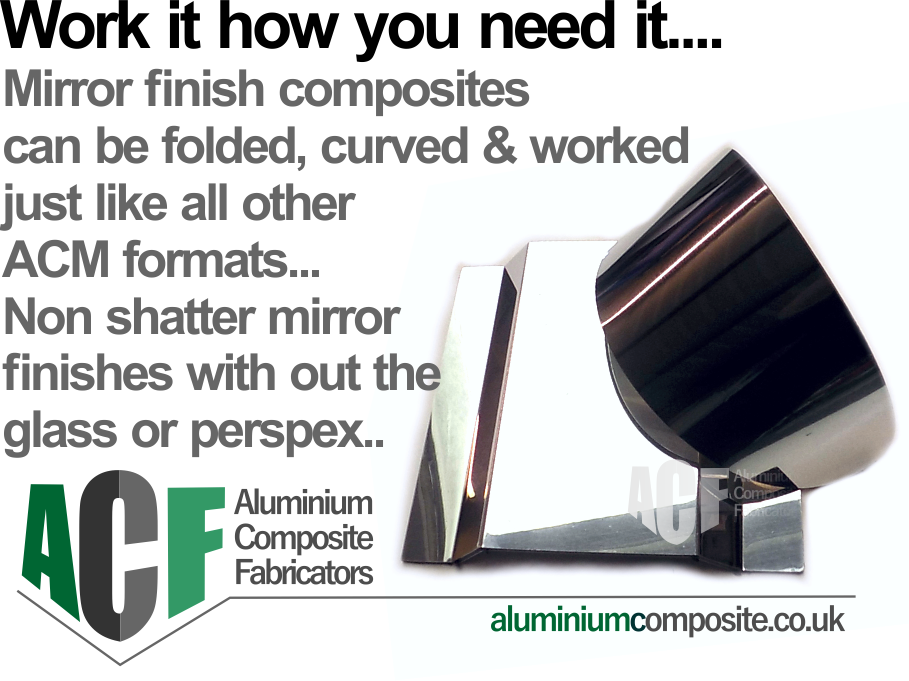

Mirrored ACM panel

A polished finish.

Mirrored ACM panel offers you attractive polished metal finishes which embrace all the benefits of normal aluminium composites.

If you have been looking at polished stainless steel or mirrored Perspex perhaps mirrored ACM can give you better results at a better price?

Lightweight.

Stainless steel is heavy, even a relatively thin 1.2mm gauge sheet will take two people to lift. By comparison a 3mm thick sheet of mirror ACM is incredibly light; an easy lift for one person. This inherent lightness means mirrored ACM panels and assemblies are much easier to position and install. Don't forget; you still get the benefits of the aluminium composite technique; if you need to trim or skim on site you can make modifications easily with saws and other woodworking tools. There is no need to reach for the grinding disc, no need to worry about Bluing or heat distortion.

Polished stainless is the nearest solid metal equivalent to this product; the finish levels are comparable, the sheet sizes are fairly closely matched. If you choose mirror ACM you get a substrate which is cheaper, lighter and more user friendly. Depending on what your criteria are this type of mirrored composite could be worth considering just for the savings in weight and on site workability.

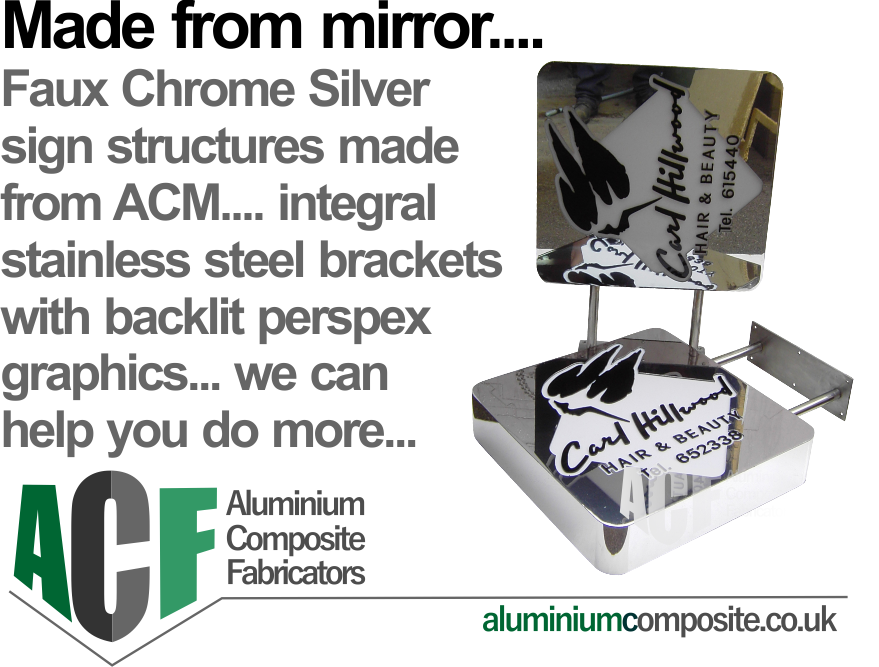

Versatile.

As you can see from this picture we've used mirrored ACM panel as the raw material for a couple of double sided signs. This type of product is normally made from polished stainless but ACM can do the same job in a lighter way.

The only parts made from "proper" metal are the stainless steel wall brackets; everything else is mirrored aluminium composite & acrylic. With a bit of knowhow and careful design there are lots of ways mirrored ACM could be used to deliver a lighter weight, more cost effective solution.